Class 104 BRC&W 2, 3 & 4-car DMUs

Interior

The tubular framed seating was a high backed design unique to the BRC&W Class 104 and Class 110 types. They were upholstered in Dunpillo and coverings differed for LMR and NER vehicles, as did wall coverings. Self coloured anodised light alloy luggage racks ran the full length of saloons.

Standard BR bodyside windows with sliding ventilators were used, the window frames and panel beading were made from wood (most DMUs had alloy frames and strips). Blinds were fitted to the second class windows, with curtains in the first class. Beclawat full-drop balance windows were fitted to the bodyside doors.

Floor coverings were a blue carpet over linoleum in first class, and a green shade of linoleum in second. Toilets were finished in primrose yellow plastic with furnishings to match.

There was good use made of fibreglass in the construction, for the cab roof and ceiling, front and side cab interior finishes, and alarm valve covers, which were in a dove-grey finish. It was also used for the covers over the heating ducts in vestibules, in a shade to match the anodised aluminium kickplates on the vestibule bulkheads.

Communication between the driver and guard was by electric buzzer, and there was an electric bell system that warned both driver and guard if any engine went on fire. Smith's Industrial Instruments provided the speedometer equipment, with Smith-Stone speed indicators, and a Smith-Stone distance counter on one axle of each power car. The cab controls were laid out in a manner similar to other manufacturers. The cab windows were 1/4 inch armoured glass, with Laycock pneumatic windscreen wipers, some fitted to both sides, some vehicles had one fitted to the drivers side only. Although not fitted when new on the first units, a Trico-Folberth window washer was added.

Heating

Two S. Smiths & Sons fuel oil burning heaters were provided per car, each operated independently. One used fresh air from the outside and the other used recycled air. Ozonair filters were fitted to both systems between the air intake and the heater. The air was fed through longitudinal ducts along the bodysides and distributed at floor level. There were two feeds into the van through the partition, capable of being blanked off at the guards discretion, and another feed to near the guards seat. The drivers' cab and toilets also had feeds through the partitions. Warm air, and cool air from a grille on the front of the cab under the secondmans window, was fed into a mixing chamber which had a flap valve allowing the temperature to be controlled for de-misting and de-frosting. This was aided by an electric driven fan which blew the air to the distributing duct at the bottom of the drivers window.

London Midland Region finishings

First class was trimmed in a blue shade of uncut moquette (with a "floral shaped" vertical stripes) and contrasting blue Vynide panels on the seat frame and back panel, and had armrests and headrolls.

Second class seating was trimmed in cut and uncut maroon moquette (with a narrower fawn/buff/light brown type colour vertical pattern approx. 1" wide), and grey green Vynide panels in the seat frames and back. Headrolls were provided, but not arm rests.

The moquette and vinyl patterns and colours in first and second class was identical to that used in the West Riding and West Cumberland Derby Lightweights, the use of the vinyl to divide seats was in a similar style but there were differences.

In the first image is a first class saloon, viewed from the cab end, a second class saloon is shown in the second image.

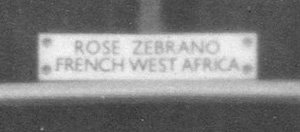

Walls were finished in polished veneered plywood. The first class was rose zabrano and the second class lacewood or English cedar. The type of wood was identified by a small plaque inside each saloon on the vestibule walls above the archways (this sample from above the door in this image):

Vestibule bulkheads were formed from blockboard and veneered to match the saloons, with windows of armoured glass. The interior sliding doors were also blockboard but veneered in mahogany to match the mahogany framing in the bodyside and bulkhead windows.

When first delivered there were complaints from the public that the ashtrays were useless. Replacement was advocated. Yet when the price to change them to a larger type was found to be 15/- each, it was decided that no further action be taken.

When new the London Midland Region DMBSs had the front saloon designated non-smoking with a sliding door fitted to access the saloon from the vestibule. On Eastern Region vehicles this was just an open partition into a smoking saloon.

The colour images shows interiors in later years and clearly shows the effect of the veneer finishing. The seats have been recovered since new, one has a black / grey moquette and the other a blue / green pattern (some with vinyl headrolls, some not!).

North Eastern Region finishings

Wall coverings were light blue formica in first class and light green in second.

Seat coverings were a different pattern of moquette from the LMR sets, having the same scallop shell / fan pattern on both first and second class, and previously used on Met-Camm sets. Colours were blue in first class and green in second.

All the non-brake vehicles built for the Eastern Region had a luggage rack area opposite the toilet. One double seat was omitted to accommodate the rack, and the triple seat backing onto the toilet was replaced with a double.

The door vestibule end of the TC and TS vehicles and the gangway ends in all vans were fitted with the same sized windows as the cabs, one either side of the gangway.

Refurbishment

The vehicle part of the main 1970s 'Refurbishment' programme, but some vehicles were given a mini-refurbishment by Newton Heath, Buxton or Carlisle Currock.[1] The repairs were classified as 'DUG 57' (possibly Diesel Unit Upgrade?) and some Class 105s were also treated. The work done varyied between sets, but typically involved a retrim with blue-green checked moquette, with either blue-green or blue PVC headrolls, the wooden interiors cleaned-up or wood renewed. The tungsten lighting was retained. Some had orange interior panels in the vestibule areas. At least one vehicle, 50524, had NEWTON HEATH add on the cab front under the drivers window.

In the image 50432 can be seen to have orange applied in the vestibule areas, at least to the lower door panel.

Power cars noted as treated

50435 DUG 57 29750 8-80

50436 NH Bogie Change (DUG 57) 2-12-79, Carlisle Trim 3-12-80

50440 NH Bogie Change (DUG 57) 2-79, BX DUG57 15-1-81

50449 Carlisle Trim 26-6-81

50450 Carlisle Full Trim 2-81

50463 NH Bogie Change DUG57 28-9-79

50468 NH 12-80

50480 6-81

50481 BX (DUG 57) 15-1-81

50483 NH Bogie Change and DUG 57 17-11-79

50488 Carlise 1-81

50490 DUG 57 29750 8-80

50515 DUG 57 29750 6-80

50524 NH DUG 57 29750 16-2-81

50542 LO DUG 57 17-2-81

50461 DUG 57 29750 5-81

And centre cars:

59133 Carlisle 9/80, BX DUG57 15-1-81

59141 Carlisle Full Trim 7-3-81

59146 DUG 57 5-80 (Had Bogie Change at NH 19-4-80)

59147 NH Bogie Change and DUG57 11-8-80

59151 Carlisle Full Trim 26-6-81

59171 DUG 57 7-80

59176 NH 12/80

59184 NH Full Trim 9-80

59188 DUG 57 9-80

59207 NH 12-80

References

- ⋏ Notes from Eddie Knorn and John Thomlinson

Summary

Ordering Details

Description

Interiors

Modifications

Single Engine Conversion

2-car diagrams & Works Pics

3-car diagrams & Works Pics

4-car diagrams & Works Pics

Numbering & Drivers Instructions

Liveries

Operations - Early Days

Operations - Later Days

Operations - Scotland

Accidents

Decline

Non-Passenger Use

Images

Details about preserved Class 104s can be found here.

Many thanks to Kevin Dowd for his assistance in the preparation of these pages, and to Eddie Knorn for further data.