Throttle Motor

Description

by John Joyce

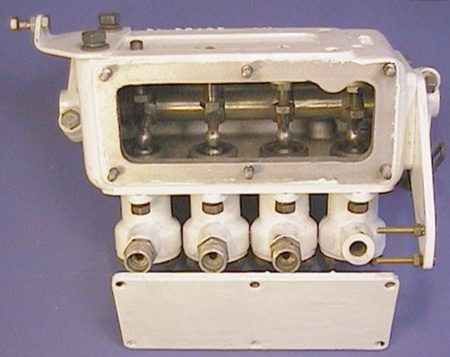

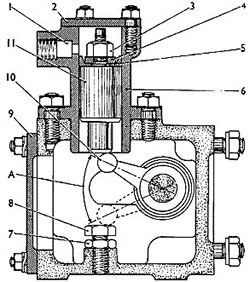

The throttle motor is the device which controls the supply of fuel to a diesel engine in response to the driver's power controller. Details of how this is achieved are in the DMU course notes. Problems encountered with the unit are mainly due to sticking air pistons and seized-up internal gubbins. (note: 'gubbins' is the technical term for the mechanical part of any item with more than two moving parts) The air cylinders can be removed and serviced whilst leaving the rest of the unit in-situ, and this is sufficient for many repairs. If the gubbins gives trouble, it will be necessary to remove the throttle motor for servicing. Amazingly enough, despite all the oily crud and gunge thrown around underneath, things still manage to seize up.

How It Works

There are four air cylinders at the bottom of the unit, one for each of the power positions. Each piston pushes an arm up inside the throttle motor, turning the main shaft; a crank on the end is connected to the governor, controlling the injection pump. A crank on the other end is connected to the hand throttle control. It's pretty obvious if you take the side cover off and look.

Problems:

Sticking pistons

- one (or more) power position either doesn't work, or causes an engine to rev up even

after closing the power controller. If a particular position doesn't work at all,

remove the side cover and check adjustment before dismantling further.

Leaky piston seals

- pretty obvious from the sound of escaping air inside the throttle motor when one EP

valve is operated. Seized gubbins - can have varied effects depending exactly what has

seized up.

Poor setup

- often the throttle motors on the various engines on a set aren't all set up the same.

This makes driving more difficult in wet / icy weather as one engine tries to do all

the work, causing wheelspin. Driving is a lot easier and more enjoyable if they are

set up properly.