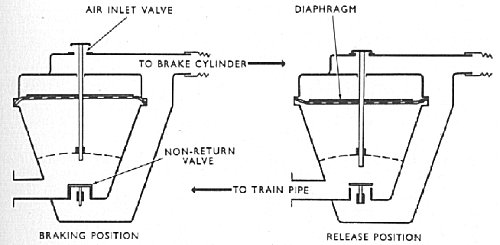

This valve, commonly known as a 'DA Valve', is fitted close to the vacuum brake cylinder. In the 'running' position the air inlet is closed and the whole of the interior of the direct admission valve is at 21". When a brake application is made, some air enters the train pipe and provides a greater pressure on the underside of the diaphragm, which opens the air inlet valve to atmosphere, and the brake will be applied since air is entering from the air inlet valve and not from the train-pipe.

The advantage of this arrangement is that the air let into the system to apply the brake does not have to pass through the driver's brake valve and thence through the train-pipe to the various brake cylinders on the train. The train-pipe is rather 'passing a message' to each of the direct admission valves, which open to atmosphere and allow uniform application of the brake to be achieved more rapidly.

When the brake is released the vacuum in the train pipe is brought back to 21" air is withdrawn from the underside of the brake cylinder pistons, past the non-return valve at the bottom of the direct admission valve and so out through the train pipe. The diaphragm returns to normal 'running' position and the air inlet valve is once more closed.

General Description

Operation

Exhauster

Feed Valve

Isolating Valve

Brake Cylinder

Direct Admission Valve

Driver's Brake Valve

Maintenance:

Adjusting Brakework

Feed Valve Overhaul

Isolating Valve Overhaul