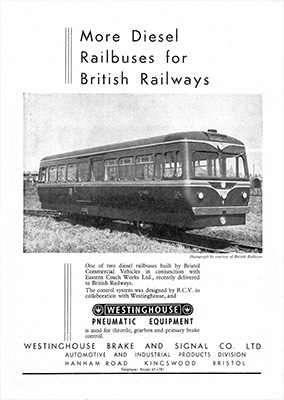

Bristol Commercial Vehicles / Eastern Coach Works Railbus

Power Train

The single Gardner 6HLW 6-cylinder engine had a 8.4 litre capacity, delivering 112bhp at 1,700rpm, and was flexibly mounted below the body floor at the centre of the vehicles. Instead of having a normal dipstick arrangement to check the oil level, an engine oil dispenser was fitted which automatically topped up the oil sump from a reservoir tank. A sight glass gauge, visible from the outside of the vehicle, showed when the reservoir tank required filling. The engine air intake was taken from the roof by ducting for cleaner air.

A single 38 gallon fuel tank was mounted below floor level at the end on the vehicle and supplied both the engine and the heater.

A flattened tube type Coventry radiator was fitted between the engine and trailing axle. The header tank and filler cap were at the side of the vehicle and accessible through a suitable aperture in the skirt panel. The coolant capacity of the system was about 10 gallons.

The battery was an Exide type 3 BMF 17/2 of 296 A-hr capacity, charged by a CAV AC generator (type 824/2) via a rectifier and 24V dc control board. The alternator was driven by a vee-belt from the front end of the gearbox.

The hydraulic auxiliary throttle control was supplied by Automative Products Co Ltd.

Transmission

The engine was fitted with an 18 inch Self Changing Gears Ltd fluid flywheel unit incorporating a centrifugal lock-up clutch to provide a positive drive at speeds above 700rpm. The output was connected the gearbox through a short cardan shaft with a free-wheel unit. Transmission control was fully automatic from standstill to maximum speed. The Self Changing Gears Ltd five speed (overdrive) epicyclic R11B gearbox was arranged for fully automatic gear selection and engagement by the SCG Ltd VS automatic control system (a Derby Lightweight set had been trialled with this). Gear engagement was by air pressure, controlled by Westinghouse electro-pneumatic valves operating in response to signals from the VS automatic control system. The control system was evolved by Bristol Commercial Vehicles in collaboration with Westinghouse and Self Changing Gears. Westinghouse pneumatic equipment was used for throttle and brake controls and for gearbox operation.

The drive continued from the gearbox via another cardan shaft to the double reduction final drive unit. The single driving axle was a Kirkstall pot-type steel forging, similar to a bus or heavy lorry axle except that it had no differential. There were two spiral bevels for forward and reverse, which were engaged by dogs operating from air cylinders. An interlocking device prevented any movement of the vehicle until the dogs were correctly aligned. A manually operated neutral position allowed the vehicle to be towed if necessary. The wheels on the trailing axle could revolve independently.

Summary

Ordering Details

Description

Power Train

Brake System

Interior

Diagrams & Works Photos

Delivery

Demonstration

Operations

Final Days

Images

Neither were preserved.