Class 120 Swindon 3-car DMUs

Description

They had much in common with the Class 126s, although the passenger accommodation was revised for their different duties. The underframe, floor, bodysides and roof all formed an integral construction, with stress-bearing steel panels. The underframe was lighter than the 126's, and they had screw couplings instead of buckeyes (the only Swindon cars to do so). The floor was formed of 14 s.w.g. corrugated steel sheet welded to the underframe sections, and the body and roof panels were of 16 s.w.g. sheet. The interior side of all panels and roof plates were sprayed with asbestos, and the corrugated floor was packed with asbestos and covered with insulating board.

The guards vans were at the rear of the vehicles, unlike the 79xxx Inter-City sets which had received much critisism over the passengers lack of forward/rear view. The image shows the details on the rear end of 51782 while at Ayr depot. When new there were addition footsteps (where the clusters of bolt heads are) and no silencer on the exhaust, the exhaust would have been covered in grille to prevent staff touching the exhaust while climbing the footsteps. Bill Hamilton.

The standard BUT power train and control equipment was used, with 150hp AEC engines and S.C.G. Wilson epicyclic gearboxes. This gave about 5 3/4 bhp per ton of tare and about 5 bhp per ton fully laden. They had a maximum speed of 68mph. Over the years Leyland engines were fitted, the first being to 50674.

As on most DMU sets, the handbrake was operated by a wheel in the cab, and Graviner automatic fire protection equipment was fitted. This was mounted over each engine and discharged chlorobromethane onto the engine if it became seriously overheated. The engines were also protected by a low water shut-down switch, which shut of the fuel to the engine if the water in the header tank fell below a certain level. An oil pressure switch also shut down the engine if the pressure became too low. The operation of these devices was immediately brought to the attention of the driver by warning devices in the cab.

The drivers controls in the cab of a Class 120 set. Almost identical to the 1959 Class 126 sets, the main difference being the switch panel between the throttle / gear controllers. Michael Kaye 55A.

Some of the Cardiff based sets were later equipped with headlights for use on the Central Wales line.

Sets had a mixture of oval and round buffers. Grilles covers were fitted around the exhaust where it rose either side of the gangway. 59301 had B4 bogies fitted at some point.

When delivered, they were described as being able to be re-marshalled into 5, 7 or 8-car sets, which may account for the different number of trailers built.

Cab Front Design

Batch One

As built the batch one (Western Region) and batch two (Scottish Region) power cars had identical cab fronts.

They had a four marker light arrangement, one on top and three on the lower cab which mimicked the lamp arrangement used on steam locomotives. The marker lamps fittings were standard to many DMUs with a slot to fit a red lense over the front, almost certainly never used, and the handrail between the two cab windows was probably added to aid reaching the top lamp safely.

The box containing the destination blind stood proud of the cab front.

Batch Two

While the cab front design itself was the same as batch one, the buffers were different between the two, batch one having the round style and batch two having the 'cut' style. Soon after, by the yellow panel era, many of these Scottish vehicles had the right one replaced with an oval one.

This vehicle is seen carrying a oil burning tail lamp, the marker lamps were not used as tail lamps till many years later.

Batch Three

These were built a few years after the others when the use of four-character headcodes was standard, and this removed the need for carrying four lamps, and so just one lamp was fitted.

The lamp brackets were moved outwards, and the style of buffers changed again to the oval type.

When the use of headcodes was abandoned the glass front would often have a yellow panel fitted with two round lenses.

In later years the cab fronts would be standardised, the four-character headcode box or lower centre lamp being removed, and a second lamp added to the batch three vehicles. On batch one / two vehicles the top lamp fitting would be removed but the mounting plinth remained identifying them from batch three vehicles. The other identifier for batch three vehicles, the position of the lamp brackets would vary when the ends were rebuilt, some having brackets placed to match the batch one/two vehicles, some having brackets fitted that extended from the buffer fastenings rather than the cab front.

Interior

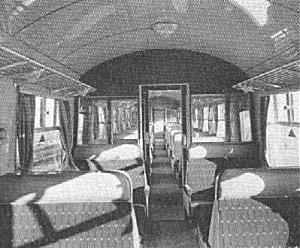

Interior side and cross panelling, and ceilings in all cars were of pastel-patterned Formica in different shades. The side walls of the first class in the DMBCs had a birds-eye maple design which was also used for the lower portions of the vestibule partitions. The partitions contained large observation windows. The ceilings were an off-white colour. In second class saloons a light green wood-grain plastic was used for the side walls and ceiling and contrasting wood-grain pattern for the end partitions. The walls in all lavatories were finished in mottled grey and white plastic, with sage grey plastic floor tiles.

The first images shows a 2nd class saloon full of 'models', a posed image for publicity purposes. They are probably Swindon Works staff as they are recognisable from similar WR publicity images. The second image shows an empty 2nd class saloon.

Metal fittings were generally finished in natural anodised aluminium. Lighting was by circular fittings in the ceiling, supplemented by small tubular lights over each set of seats, incorporated in the aluminiun luggage racks which ran the complete length of both sides of the saloons. Curtains were fitted throughout, and carpets in 1st class. Oval mirrors were fitted to saloon ends.

Heating was by two oil burning Smiths-Webasto combustion heaters. Warm air was carried in ducts underneath the floor to outlets beneath the seats. The air intake from these heaters could be drawn from outside, passing through an Ozonair filter, or in cold weather a portion of the used air could be recirculated with the selection being under passenger control. There was also thermostatic control of the temperature.

Seats were the tubular frame type, with high backs, hair and spring filling in first and Dunlopillo cushions and backs in the second class. Second class upholstery was in shades of green, with cream leatherette headrests. First class was upholstered in moquette of grey & gold pattern on a black background.

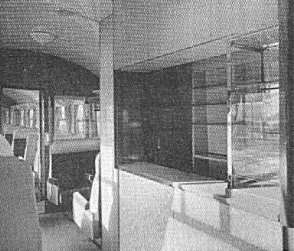

Small collapsible tables were fitted against the side walls at each pair of seats, so that refreshments could be served from the small buffet counter kitchen. This had a small hot-water boiler burning propane stored on the underframe and an electric refrigerator, store cupboard, sink, display cases and shelves. The shelves were finished with a light coloured plastic. The front of the counter was in the form of hinged flaps which could be raised and locked when closed. Plastic panelling above and at the sides of the buffet counter was in a medium Australian walnut design. An electric extractor fan was fitted in the ceiling. Opposite the buffet were four wall seats.

Hot water for the toilets was provided by electric heaters.

In the mid-'70s the curtains were removed due to costs, and in 1983 all the 1st class saloons were declassified to 2nd. The buffets saw limited use, and before long they were regarded as trailer seconds. By the mid '70s the facilities were made redundant, but left in situ.

Variations

Western Region

Ordered in May 1956, the first batch were all delivered with WR ATC apparatus. Made up of a DMS, TLSRB and DMBC, they had 18 1st and 144 2nd class seats, and 130 sq ft of luggage and parcels space. The total empty weight of approx. 103 1/2 tons represented 1,400 lb per seat. There were 49 of each power car and 47 trailers in this batch.

The third batch, 9 of each power car and 10 trailers, did not have the buffet section.

Scottish Region

The original seven ScR brake vehicles had tablet apparatus fitted to the solid half of the double doors in the van (pictured). These were still being used when passing Forres signal box as late as March 1980.[1]

References

- ⋏ p158 April 1980 Railway Observer (Railway Correspondence and Travel Society)

Summary

Orders

Description

Modifications

Refurbishment

Diagrams & Design Codes

Works Photographs

Numbering & Driving Inst.

Liveries

Operations

Operations - Central Wales

Operations - LMR

Operations - Scotland 1958-81

Operations - Scotland 1986 on

Decline

Parcel Use

Images

Details about the preserved Class 120 vehicle can be found here.