Class 123 Swindon 4-car DMUs

Description

The underframe, floor, bodysides and roof on each car formed one integral structure capable of withstanding all working loads. The bodies and underframes were made entirely of welded steel, the body frame from pressed steel members and the underframes from rolled steel sections and plate. The leading end framing of the power cars was specially strengthened.

On the power cars the rainstrip wrapped around the front end and so the leading handrail at the drivers door was hollow and connected to the rainstrip to provide drainage at that end. Their strangest design feature was that yet again Swindon failed to provide any marker / tail lights, meaning the guard would have to attach a tail lamp to the rear and move it to the other end when changing direction. In later years, when the route indicators were obsolete, they were plated over and lights fitted.

BUT supplied the power equipment, with two 230hp Leyland Albion 902 engines on each power car, fitted with 22in fluid flywheels. These were fitted with short cardan shafts to four speed epicyclic SE4 gearboxes. Vee belt pulleys at the input end of the gearboxes drove the battery-charging alternators and the exhausters for the vacuum brakes. Longer cardan shafts connected the gearboxes to the final drives in the inner axle of each bogie, these drives incorporated forward and reverse gears.

Each engine had its own cooling system, thermostatically controlled to enable running temperature to be reached quickly. Engine throttles, gearboxes and final drives were all pneumatically controlled and electrically operated from the drivers cabs. Compressed air was supplied by compressors mounted on the engines and stored in underframe reservoirs.

The narrow cabs had displays for each engine for the maximum six power cars that could be connected, showing that every engine and final drive was operating correctly and engaged. Loudaphone equipment was provided for communication between the driver and guard. An adjustable upholstered driving seat was fitted, with an extra tip-up seat for a second man in the vestibule outside.

Years of complaints about rough riding in other DMU vehicles was finally addressed by the fitting of the new B4 bogie, pictured above, which gave good results at all speeds. And as a good bit of the passenger accommodation was now formed from compartments, these were one of the most favoured sets with passengers. The only complaint may have been that there was no forward vision through the drivers windows, as the DMBS had the guards van directly behind the cab, and the DMS had compartment seating. The power cars had a heavier version of the B4 bogie, B5s, which were adapted to take a final drive.

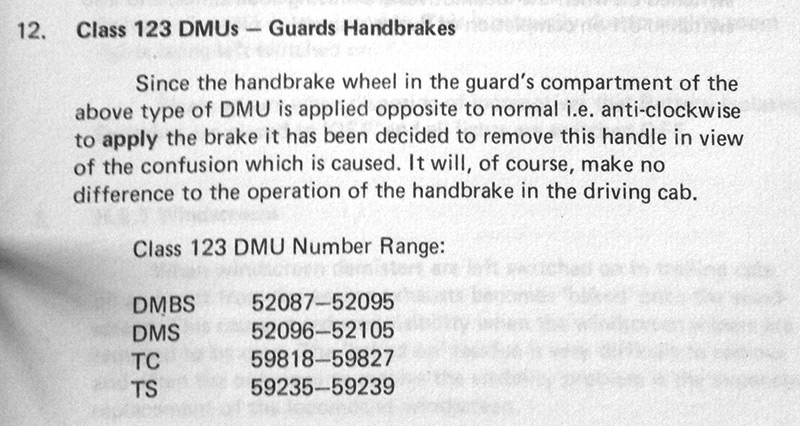

One of the many modifications made to the Class is detailed in this excerpt from LMR Traction Bulletin Issue 38 (March 1984):

Summary

Description

Interior

Diagrams & Design Codes

Works Photographs

Numbering & Driving Inst.

Liveries

Operations

Non-Passenger Use

Images

No Class 123 vehicles were preserved.