Derby Lightweight (Yellow Diamond) 1, 2 & 4-car DMUs

Ultrasonic Test Train

West Cumberland vehicles M79018 / M79612 became DB975007/975008 forming the Ultrasonic test train for the Civil Engineers Department operating from 1970 till 1994.

The British Railways Board commissioned the building of the Ultrasonic Test Train in 1968, and it was decided that withdrawn Derby Lightweight vehicles would be suitable for conversion. Vehicles 79185 (withdrawn from Bletchley in January 1968) and 79612 were selected (withdrawn from Upperby in April 1967) and sent to the research centre at Derby. Once there there was the realisation that 79185 was fitted with an automatic gearbox and would not be suitable for the new task, so an alternative would be sought.[1]

From a batch of withdrawals of West Cumberland vehicles 79018 was selected as the power car in the best condition and dispatched to Derby, arriving on Wednesday, 8th May.[2]

Philip C Johnson was responsible for many of the modifications to the vehicles. He noted:[3]

- The units were initially fitted with Lead Acid accumulators when in service prior to our conversion. It was recognised that with the continuing drain on the batteries even when left unattended over periods then Nickel Iron (NiFe) batteries would be more suitable for long term reliability. This is because they do not deteriorate if left for extended periods in a discharged state unlike Lead Acid ones. With their lower output voltage additional cells were fitted to bring the total voltage back up to the required level.

- When the units were in operation with me we carried a spare throttle motor and one or two spare EP valves in the under floor storage space in the Trailer Car.

- When in operation as the test train on BR we fitted with as many air tanks as we could get on as this was a premium for operation of the trolley.

- The original end jumpers were removed during the conversion and the various control cables were incorporated into junction boxes in the end of the vehicles.

- The stop button was modified during conversion so that when power was lost the system was automatically shut down.

The trailer car would carry all the technical equipment, the power car would become a staff / dormitory vehicle. This included bunk beds, which were constructed without knowing the sizes of mattresses — the beds then had to be altered to suit. [4]

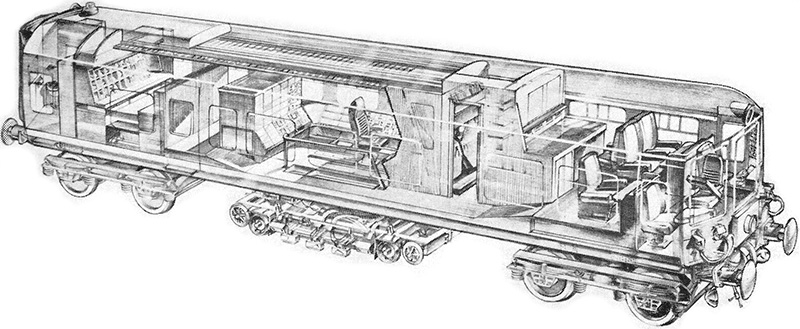

The drawing shows the interior layout of DB975008.

The equipment operation control position on DB975008. The operator can monitor the signals being recorded on film and the operation of the camera, and adjust the positions of the ultrasonic probes.

The floor at the control desk area on DB975008. It shows two flaps opened up to show access to equipment and the floor windows which allow observation of the probe trolley.

The two generators in the former brake van of DB975007. The inner rail around the top is part of the fire suppression system similar to that fitted above DMU engines.

External changes

On the power car, drivers side, the front vestibule doorway was plated over and a half width window added. Between the van doors and the vehicle end ventilator grilles would be added to the lower bodyside, this is presumably where the generator was. On the opposite side the second sidelight (rear of the front saloon) was plated over.

On the trailer car, both front vestibule doors were plated over, as was the rearmost full sized window on the non-drivers side.

On the cab fronts of both vehicles a protruding rectangular box was added under the centre cab window, this had a marker lamp fitted. There was an additional step added to the cab corners, attached using the bolts for the buffers, and a windscreen wiper was added to the centre cab window.

All remaining passenger doors, and the guards inward opening doors, retained the window bars over the droplights. All sideboard brackets (just under cantrail level) were left in place.

Operations

A brief summary from Philip C Johnson:[5]

The UTU1 test train came into service in Dec. 1970 using sliding probes capable of about 120miles per shift at 20mph using some 5 tons of water. It originally had its results recorded on continuous 35mm film. This was manually examined by manual film readers located at my office in Paddington. The task was very onerous and it was very difficult to get and keep committed staff to carry out this work. Consequently it was only possible to analyse about 2000 miles per year. The examination was supplemented by teams of hand testers working in conjunction with the train both independently testing to a programme as well as confirming the defects located by the train.

During the 70's digitisation was a new facility coming in and a contract was placed with Harwell to eventually record the salient information digitally on magnetic tape. This was then checked at the office the following day by a couple of staff. This enabled the amount of testing to be increased through the 80's to about some 10,000 miles per year. Unfortunately by this time the reliability of the unit was becoming a problem both electronically and mechanically and a new unit with wheel probes was proposed.

Liveries

For most of its career the vehicles were in a plain Rail Blue livery with yellow ends. In the early period both cars carried 'Ultrasonic Test Car' in the centre of the bodysides on one line, with smaller text on each side in two lines 'Chief Civil Engineer British Railways Board' and 'Equipment Supplied by Wells-Krautkramer Ltd'. This can be seen in the picture of the trolley above.

By mid-1976 the bodyside text carried had been revised, now being 'Ultrasonic Test Train' with 'British Rail Headquarters Chief Civil Engineers Department' underneath in smaller text. The image shows this on the number one (drivers) side of 975008. Stuart Pearce.

By 1986 the vehicles were in a blue grey livery, with a red band at waist level. 'Ultrasonic Test Train' lettering was on the centre of the red band on the trailer car and 'Mobile Track Assessment' on the power car. On each car the number was only carried on one side, the non-drivers side, with 'BRB HQ' added before it and above was 'Director of Civil Engineering'. The BR logo was carried on the left hand end of each bodyside.

In use they were commonly noted carrying headcodes 5Z08 for running site to site and 9Z08 when testing.

Their normal operating base was initially Old Oak Common, in 1980 it switched to Reading.

They were on display at the Stratford depot open day on 9th July 1983.

The image shows the pair at Reading on 25/7/88. Hamish Stevenson.

Eric Stuart recalls one experience about the Ultrasonic Test Train - "I was a driver on the Met at that time and had gone to Moor Park to relieve a driver on an Amersham train. Whilst waiting, the DMU came through at about 15mph, followed shortly by the train I was to pick up. The driver got off and I set off toward Amersham. We stopped at every signal for 5 minutes or so, as the dmu continued its funereal journey. We eventually got to Amersham over half-an-hour late.

Almost immediately, the following 115 to Aylesbury arrived. At that time, the service was hourly and the 'box at Gt Missenden was switched out except in peak-hours. As far as I know, the 115 had to wait over half-an-hour for the test unit to clear the section to Aylesbury or probably to the IB signals somewhere near Wendover.

When I got back to Ricky depot, the SM had been talking to the Controller. It seems the test unit was supposed to have travelled at normal speed to Amersham and then do its test run (15mph or whatever) to Aylesbury. Some wires had been crossed, with lack of amusement all 'round."

They were withdrawn in 1994 and later preserved after asbestos removal at Doncaster Works.

References

- ⋏ Minutes of meeting at Derby, April 16, 1968

National Archives - AN129-181 Ultrasonic rail flaw testing coach - ⋏ LMR Memo: General Manager to Chief Operating Officer, May 9, 1968

National Archives - AN129-181 Ultrasonic rail flaw testing coach - ⋏ E-mail Philip C Johnson to Stuart Mackay 8th March 2004

- ⋏ Comment by "willowbrookregal" on an image of the vehicles on flickr, accessed 10 August 2023

- ⋏ E-mail Philip C Johnson to Stuart Mackay 12th November 2023

Summary

Description

- Single cars

- Four-car sets

Drivers Instructions

Numbering

Liveries

Operations

- West Cumberland

- Lincolnshire

- East Anglia

- North Eastern Region

- Buckingham - Banbury

- Manchester

Non-Passenger Use

- Special Saloon

- Ultrasonic Test Train

Images

Details about preserved Derby Lightweights can be found here.