Derby Lightweight (Red Triangle) 2-car DMUs

Body Design

Here we look at the design and the materials used to construct the body of the vehicles. Much of the information on this and the two construction pages has been extracted from a paper by A.E. Robson for a Symposium on "The Use of Aluminium in Railway Rolling Stock" in 1960 produced by The Institution of Locomotive Engineers and The Aluminium Development Association.

The use of aluminium had been tried on railway vehicles in the past, the Lancashire & Yorshire Railway (L&YR) and the London, Brighton and South Coast Railway had used aluminum for exterior panelling on timber bodies as far back as 1905 and 1909 respectively. The L&YR then built the Manchester - Bury electric vehicles in 1916 with a steel underframe / body framework. Aluminium panels were used on the outer side, end and roof panels, some inner panels, and also many other interior fittings. This saved about 0.75 ton per car, and the vehicles were in traffic for over forty years with only slight corrosion, mainly where the aluminium was in contact with the steel.

After these vehicles were built aluminium was considered by builders now and again, but the price of of steel was considerably less than aluminium, and the ease of welding steel meant steel construction became the norm.

The first of the British Railways DMU vehicles were ordered for the West Riding Leeds - Bradford service, which had fairly severe gradients and five intermediate stops on the 9 1/2 mile route. There was a need to improve upon the steam timings to stay competitive with road transportation. The vehicles had to have a good route availability as the intention was to use the same design for other routes once experience in service was gained. To provide the best power / weight ratio possible, light alloy vehicles were required, with the length over headstocks restricted to 57ft.

To fit in all the power train and control equipment on the underframe between the bogies, a traditional coach design with a self-supporting underframe could not be used, the trussing would take up too much valuable space. Instead the bodyframe, underframe structure and panelling was designed as an integral unit in order to achieve lightness combined with strength. Together they formed a load-carrying construction capable of withstanding a static end load of 80 tons, plus twice the passenger loading and luggage, without permnanent deformation.

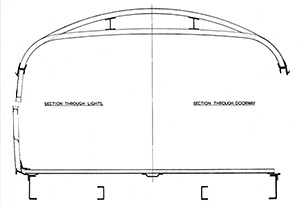

The structure was considered as a Vierendeel truss for stress analysis, which comprises top and bottom booms connected by means of vertical columns. The section drawing shows the top and bottom booms, the top boom was considered to include the top light rail, cant rail, roof purlins and a small portion of 10 s.w.g. bodyside panel (but not the 14 s.w.g. roof panel). The bottom boom was considered to include the bottom light rail, intermediate rail and bodyside panel, in addition to the main underframe members. As can be seen in the right side of the drawing, the boom sections are reduced at doorways. The vertical columns connecting the top and bottom booms were considered to include the bodyside pillars and bodyside panels.

Calculations showed that the highest stresses were in the top boom at the doorways and the adjacent pillars. Deflection at the centre of the body with 100% passenger overload was estimated to be 0.21 inch, which was confirmed with the actual load tests.

The co-operation of the Metals Division of Imperial Chemical Industries (I.C.I.) was sought at the design stage to help select a suitable alloy. The material chosen for all main structural members and panels was known as 'Kynal' M.39/2. This was a fully heat-treated aluminum magnesium silicon alloy. Later ICI began using an image of a Derby Lightweight in many of their adverts as seen here, more examples can be found here.

The material had an ultimate stress of 20 tons per sq/in. with an

elongation of 10%. This met these standards:

BS.1470 for sheet and strip,

BS.1476 for bars, rods and sections,

BS.1477 for plate.

After the 79xxx lightweights, the Class 108s were built using alloy

from other suppliers to the equivalent specifications.

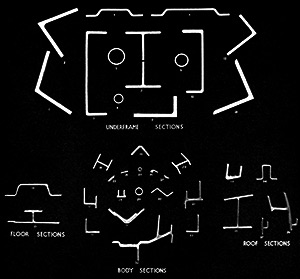

The framework was composed of 37 different extrusions, and the next image shows the sections of these. A design advantage was that the cross-sections could be individually tailored to suit each elements requirements. Also the functions of several members could be combined into one, such as the outrigger (number 32, bottom centre) and the cantrail (36, far right).

Fully heat-treated alloy cannot be welded without softing the metal in the area around the weld impairing its physical properties, so the structure was rivited together. As originally built only light alloy rivets were used, cold formed in the condition received, and hydralic pressured being used where practicable.

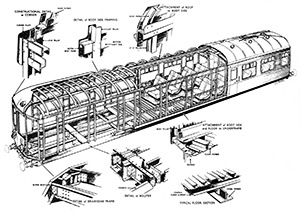

This cut-away drawing appeared in "Light Metals" magazine at the time the vehicles were new and clearly shows how the vehicle framework was constructed, and how many of the joints were designed.

The main roof and underframe members were continuous, as were the underframe cross-members passing over the top of the underframe centre longitudinals. These cross-members were positioned at the neutral axes of the vertical bodyside columns of the idealised frame.

The floor was formed of individual interlacing extrusions running across the underframe from outrigger to outrigger, secured by riveting to the outriggers on to a central floor support member. The floor members covered the whole underframe and gave a flush underside onto which asbestos insulation was sprayed.

The windows were self contained units formed of anodised light alloy frames riveted to the bodyside. The sliding lights had non-metallic inserts to avoid metal to metal contact with the fixed frame. Lazy tongue (LMS type) gangways were used, the framework and the treadplated being light alloy.

The Lightweights had distinctively angular ends, both cab and gangway ends being the same shape. I've seen it mentioned that this was in case the railcar experiment was not a sucess - the cab end could then be easily turned into a gangway end and the vehicle used as hauled stock instead!