Blue Pullman

Brakes

The trains were fitted with a Westinghouse Electro-pnuematic brake featuring a high speed control and were operated by compressed air.

The essential features were:

An electrical driven air compressor was fitted on the underframe of each motor

car, and each compressor charged its own main air reservoir to a maximum pressure

of 125 lbs. p.s.i. These reservoirs were connected to each other by a common pipe,

called the main reservoir pipe, which extended the whole length of the train.

Connected to this pipe on each vehicle was a supplementary reservoir charged with

air at the same pressure. Another pipe extended the full length of the train called

the brake pipe and could be easily distinguished from the main reservoir pipe by

its slightly larger diameter. The brake pipe was connected to an auxiliary air

reservoir on each vehicle. Mounted on the underframe of each vehicle was an

electro-pnuematic brake unit connected to both the main reservoir pipe and the brake

pipe, this unit being perhaps the most important item of the brake system. Brake

cylinders with combined slack adjuster were mounted on the heavy type bogie frame of

the trailer bogies; these cylinders in turn were connected by fully compensated clasp

brake rigging to the brake blocks.

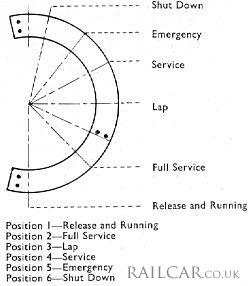

Control of the brake was established by means of a brake controller situated in each driving cab, the control handle had six operational positions as indicated in the diagram to the right.

Special features were incorporated into the Westinghouse air brake equipment to maintain the high efficiency at high speeds. Control was by electro-pneumatic valves and at train speeds at which normal braking was required the degree of standard brake pressure applied to the cylinders was proportional to the position of the driver's brake controller.

In the high speed range the brake pressure was automatically increased to compensate for the lower coefficient of friction of the cast-iron shoes when operating at high speeds. The changeover from high speed to normal speed braking, and vice-versa, was entirely automatic and was controlled by a valve energised by current from the speedometer generator. The de-luxe Pullmans were the first train to be fitted with two-stage EP braking.

Operating through switch contacts in the controller, the brake valve handle was also used to control the automatic brake for emergency use. The brake equipment incorporated the latest type of Westinghouse rubber-seated valves and O-ring packings for ease of maintenance.

Summary

Development

Press run 24/6/60

Press run 7/9/60

Staff difficulties

Ownership agreement

Manufacturer's Publicity

Description

Type 1 - LMR motor car

Type 2 - WR motor car

Type 3 - WR parlour 2nd car

Type 4 - LMR kitchen car

Type 5 - WR kitchen car

Type 6 - LMR/WR parlour 1st car

Interior

Air conditioning

Motor cars

Auxiliary power

Bogies & couplings

Brakes

Data

Sub contractors

Staff instructions

LMR services begin

LMR Publicity

LMR brochure

LMR handbills

Controversy

WR services begin

WR publicity

WR publicity brochure

WR publicity leaflet

LMR Operations

WR Operations

Liveries

Rundown & withdrawal

After service & preservation

Disposal

Maintenance Manuals

Miscellaneous

Acknowledgments & Further Reading

Images

No vehicles were preserved.