Blue Pullman

Description

The sets were built to the requirements of the BTC under the general direction of Mr JF Harrison, CME British Railways Central Staff, in collaboration with Messrs SB Warder, CEE and F Grundy, Chief Traffic Officer, and the Pullman Car Company. Mr AE Robson, CMEE, LMR was responsible for inspection and test running. Mr J Howe acted as a design consultant to the Metropolitan Cammel Carriage and Wagon Co Ltd on passenger amenities and decor.

There were only five sets built, a total of 36 vehicles. They were all of an all-steel, welded construction. The LMR received two 6-car sets which had only first-class accommodation. The WR order was for three 8-car sets which contained both first and second class areas. Both the LMR & WR trains were made up of two identical half-sets. Each of the car types were given a number from 1 to 6.

| Type 1 | LMR | Motor Car |

| Type 2 | WR | Motor Car |

| Type 3 | WR | Parlour Car 2nd Class |

| Type 4 | LMR | Kitchen Car |

| Type 5 | WR | Kitchen Car |

| Type 6 | LMR/WR | Parlour Car 1st Class |

The sets were always made up in a fixed formation:

| LMR | 1 | 4 | 6 | 6 | 4 | 1 | 132 first class seats | ||

| WR | 2 | 3 | 5 | 6 | 6 | 5 | 3 | 2 | 108 first class & 120 second class seats |

All vehicles had a full width vestibule at both ends, except the kitchen end of the kitchen cars and the cab end of the motor cars.

A complete plan for an 8-car set can be found here.

Travelling technicians

A travelling technician from the Chief Mechanical & Electrical Engineer's

Department formed part of the train crew on each train. They travelled in the

leading guard's compartment, in which a small cupboard was provided for their

tools and equipment. They were responsible for:

a) deciding which of the auxiliary engines should be used;

b) changing over auxiliary engines en-route;

c) switching on the second auxiliary engine when requested by

the Pullman Car Company conductor during excessively cold weather;

d) taking action when 'fault' lights appear;

e) dealing with technical faults in traction equipment upon

request from the driver;

f) supervision of connection and disconnection of

'shore' electrical supplies, where provided, at terminating points.

Summary

Development

Press run 24/6/60

Press run 7/9/60

Staff difficulties

Ownership agreement

Manufacturer's Publicity

Description

Type 1 - LMR motor car

Type 2 - WR motor car

Type 3 - WR parlour 2nd car

Type 4 - LMR kitchen car

Type 5 - WR kitchen car

Type 6 - LMR/WR parlour 1st car

Interior

Air conditioning

Motor cars

Auxiliary power

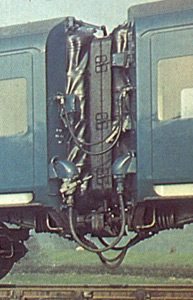

Bogies & couplings

Brakes

Data

Sub contractors

Staff instructions

LMR services begin

LMR Publicity

LMR brochure

LMR handbills

Controversy

WR services begin

WR publicity

WR publicity brochure

WR publicity leaflet

LMR Operations

WR Operations

Liveries

Rundown & withdrawal

After service & preservation

Disposal

Maintenance Manuals

Miscellaneous

Acknowledgments & Further Reading

Images

No vehicles were preserved.